At HM Tech, our commitment is to achieve excellence in customer service.

Calibration Overview

What is Calibration?

Measuring instruments are widely utilized from research and development to manufacturing and inspection. It is important to maintain and manage these standards to ensure consistent functionality and performance, regardless of when, where, or who utilizes them. Calibration results, including correction values and measurement uncertainty, are vital criteria for deciding the appropriateness of measuring instruments and product acceptability. Industries can secure the uniformity and performance of products in the manufacturing process through calibration, thereby guaranteeing the reliability of measurement results obtained during testing and inspection. This enhances the performance and external credibility of the measurement outcomes.

Calibration

較正, calibration

Calibration refers to the periodic comparison with higher standards to keep maintaining the precision and accuracy of measuring instruments, which will be valid by securing the retroactivity of measurements through linkage to the national measurement standards.

Retroactivity

遡及性

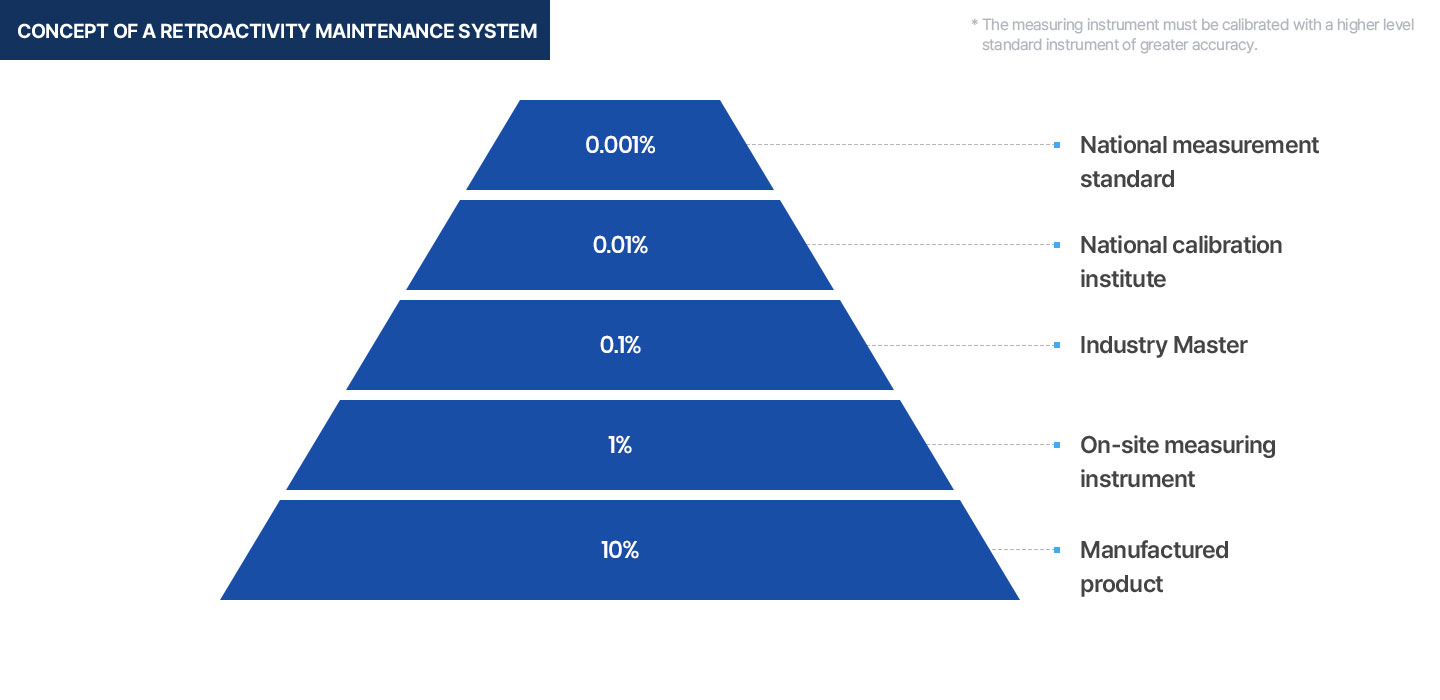

The establishment of a retroactive system of measurement involves the development, maintenance, and propagation of measurement standards across various levels, including international, inter-company, intra-company, and within different sectors of a company. This would ensure the accuracy of measurement equipment down to the finer levels within the organization.

It refers to the attributes of standard values or measurement results that can be associated with clear criteria (national or international standards) through an unbroken chain of comparisons, with all uncertainties clearly outlined.